Next-gen cryo devices deliver better results, reduce medical waste, and generate higher profits

It is hard to believe that 30 years have gone by since the introduction of canister-based devices for cryosurgery. These highly portable products had a big impact on making cryosurgery available across many specialties including pediatrics and family medicine.

Three decades ago, professional brands such as Histofreezer® (shown below) came into the market as an alternative to liquid nitrogen. Devices like Histofreezer treated a wide range of common benign topical lesions and minimized trauma to healthy tissue. Plus, they lowered the upfront investment costs of using cryosurgery. The impact of the portable forms of cryosurgery on the physicians’ office market was indeed significant. Studies estimate that physicians have treated over 500 million lesions using canister-based cryo devices. This figure certainly underscores the success of portable cryotherapy.

Cryo Innovations – What’s Next?

So, the question is, what’s next for portable cryosurgery? Are there new advances on the horizon to improve outcomes? Are there new, more efficient gases available that are better for the environment, and will new product designs make cryosurgery more user and patient-friendly?

In this article, you will learn about exciting advances in cryosurgery. Improvements that make it easier to use, increase the first-time success rate, dramatically minimize medical waste, and increase profits for the practice.

Fast Freezing of the Treatment Site is Critical for Best Results

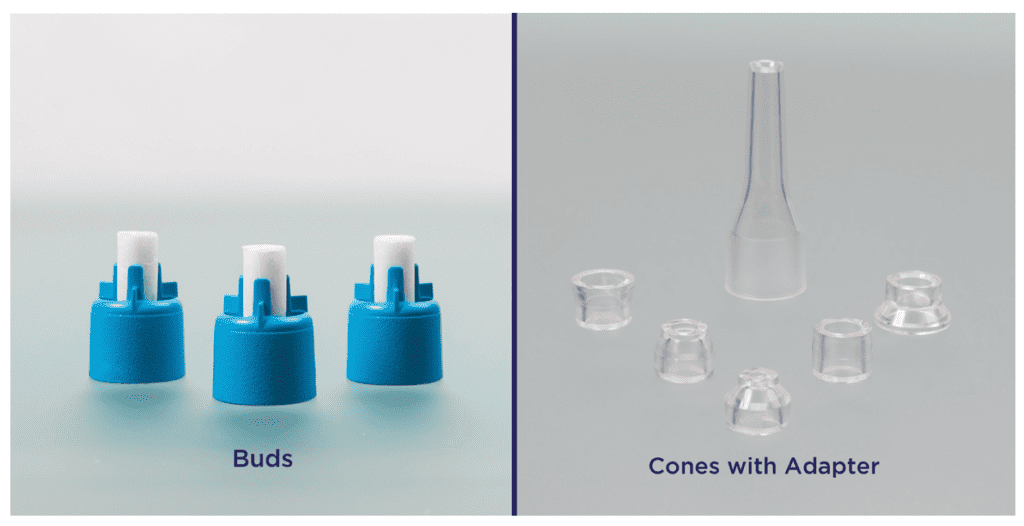

Cryosurgery works by destroying target tissue through the application of extreme cold. The application of the extreme cold is accomplished with a bud, cone, or open spray1. The process is simple but there are steps to assure optimal outcomes. Numerous peer-reviewed studies have explored factors that produce these outcomes. For example, cryosurgery works best when the temperature is sufficient to kill the target cells, freeze/thaw cycles are used and these cycles employ a rapid freeze and a slow thaw2,3,4.

For canister-based products using a bud, this is difficult because they also require a long wait time (15 or more seconds) for the bud to reach its effective freezing temperature (less than -50oC). Traditional open cones, on the other hand, allow direct application of the gas. However, the gas splatters when sprayed and rapidly evaporates, requiring multiple fills of the cone.

Killin’ It By Chillin’ It – Histofreezer® FLEX

To address these issues, new devices such as Histofreezer® FLEX from CryoConcepts, LP, use a new mixture of two cryogens (Difluoromethane and Pentafluoroethane) that immediately reach at least -52oC. To help maintain and comfortably deliver the extreme cold gas, CryoConcepts totally redesigned the kit’s buds and cones. The result was an easy to use one-handed operation that is an extremely efficient and effective method to deliver the cryogen gas using a cone or bud.

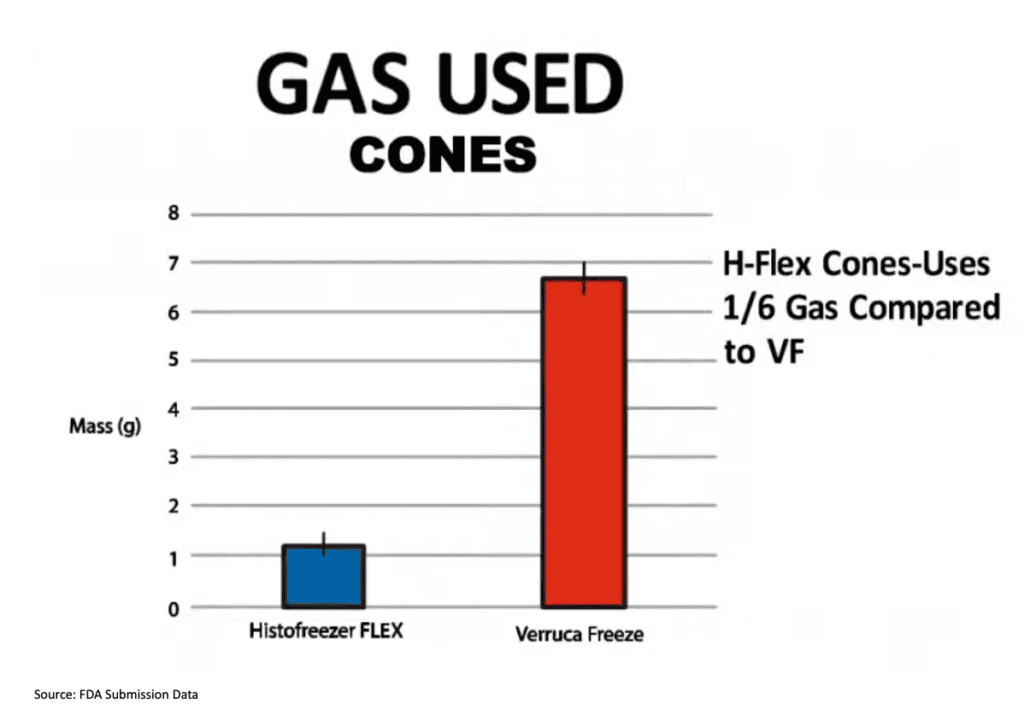

The chart below shows how much more efficient the Histofreezer® FLEX is at using gas versus a device that uses open cones. Histofreezer® FLEX uses about 1/6 the amount of gas of traditional cones which translates to more uses per kit!

Another benefit of the cryogen gases found in Histofreezer® FLEX is that they are non-flammable, have no effect on the ozone, and have one half of the global warming potential versus other older canister devices on the market.

Histofreezer®FLEX – Rethinking the design of cones or buds

Historically, cryo canister devices fall into two primary delivery categories 1. open cones and 2. buds. Research has found the physicians’ preference for using buds or cones is about 50:50 and the standard design of cones or buds has remained unchanged for over three decades.

Open cones work exactly as described. A funnel-cone is placed over the lesion and a spray of gas fills the cone. The problem is the gas splatters on the clinician and patient and rapidly evaporates, requiring a refill.

Buds, as an alternative, are made of foam that is filled with cryogen gas that must first evaporate to reach effective temperatures. Physicians lived with these limitations, but our team took the challenge to rethink and remove the historical issues when using an open cone or foam bud.

“Our goal from the very beginning was to design a device that could work equally as well with both buds or cones,” said Dr. Sam Niedbala, CEO of CryoConcepts, LP. “We redesigned the buds to improve their ability to be immediately ready to use and stay cold longer. Our closed cone design eliminates any cryogen splatter and uses less gas as compared to open cones. We have dramatically improved the delivery of cryogen gas to the treatment site, thus minimizing the amount needed to freeze the target skin lesion. Lastly, we wanted to make portable cryosurgery easier to use and made Histofreezer® FLEX so it operated with just one hand.” he added.

CryoConcepts Setting the Standard for Less Medical Waste

During development, interviews with physicians revealed high sensitivity to the issue of reducing medical waste. In fact, some report a “feeling of guilt” over the amount of waste they produce. Further, they are actively looking for products that can reduce their “environmental burden”. A good start, in this case, is putting an end to the tens of thousands of empty cryogen canisters that end up in landfills every year.

So, the goal of minimizing waste was a key design challenge for the engineers at CryoConcepts during the product development process for Histofreezer® FLEX. They identified a new canister that can be returned to CryoConcepts that can be refilled, and reused by physicians – a first in the cryosurgery market.

“Our commitment to being good stewards of the environment runs deep at CryoConcepts. We have the first reusable canister in our industry and we encourage our customers by including a pre-paid address label in every kit to make returning the empty canisters as seamless as can be,” explained Dr. Niedbala.

Better Outcomes. Improved Design. Environmentally Conscious.

Medical device makers can have challenging goals when it comes to product development. Medical professionals require new devices that deliver better results, at lower costs while being easy to use. In addition to clinical outcomes, new products must be better for the environment and reduce medical waste.

So, it is no surprise that innovation in cryosurgery has taken almost 30 years to achieve. The good news is that CryoConcepts has answered the call and has delivered meaningful innovation to the portable cryosurgical category.

Resources

Make the Switch to New Histofreezer FLEX

References

- Usatine R, Stulberg DL, Colver GB, Cutaneous Cryosurgery, 4th ed, CRC Press, 2015

- Andrews, Mark, Cryosurgery for Common Skin Conditions, American Family Physician, 69:10, 2365-2372, 2004.

- Gage AA, Baust J, Mechanisms of Tissue Injury in Cryosurgery. Cryobiology, 37, 171-186, 1998

- Thai KE, Sinclair RD, Cryosurgery of benign skin lesions, Australasian Journal of Dermatology 40, 175–186, 1999